Streamlining Operations: Manufacturing Document Management Strategies

In digital transformation, converting manufacturing documents into digital formats is critical for optimizing business processes.

The manufacturing industry is expected to grow at a rate of 3.57% annually until 2028. Smart manufacturing is a significant driver of this growth, with the global market projected to reach $860 billion by 2031. However, as manufacturing firms increasingly adopt smart technologies, they face new challenges when transitioning to the modern era.

Transforming paper-based documents into digital forms is essential to enhance efficiency and competitiveness as part of a broader digital transformation strategy. For manufacturers, this process involves using digital resources to streamline operations, ensure compliance, and drive innovation.

By integrating document scanning and cloud storage, manufacturers can evolve how they manage, access, and utilize their business data. This article provides insights and actionable strategies for successful implementation of manufacturing document management in this evolving landscape.

The Imperative of Manufacturing Document Manufacturing

The imperative for digitalization in the manufacturing sphere is undeniable.

This sector has recently been confronted with substantial hurdles, encompassing the global health crisis, supply chain disruptions, escalating energy prices, geopolitical tensions in Europe, and labor shortages. These factors have precipitated production decelerations and complexities for manufacturing entities.

To adjust to this new cluster of obstacles in the industry, manufacturers are compelled to adopt new technologies to match the velocity of demand. This process starts by converting physical documents into digital files.

Streamlining Processes and Compliance

Being able to provide a rapid and accurate audit trail is critical for compliance requirements—even more so as digital and remote audits become the norm. Yet paper-based processes remain surprisingly widespread and must be addressed. Manufacturers lacking real-time insights and data-driven decision-making capabilities will face considerable challenges if they do not convert paper-based processes to digital.

By utilizing paper document scanning, manufacturers can begin to streamline their processes. This digital transformation allows for easier document management, archiving, and retrieval—enhancing operational efficiency.

Another cost-effective option for manufacturers is to convert paper documents only when necessary. Using services like on demand scan allows companies to convert documents from storage when needed. This is a practical and budget-friendly approach that helps businesses prepare for their transformation journey.

Advantages of Cloud Storage for Manufacturers

Utilizing cloud document storage services presents a multitude of benefits and opportunities for manufacturers operating in various industries.

Scalability and Accessibility

An essential advantage of integrating cloud storage solutions into a business infrastructure lies in scalability. The flexible nature of cloud storage enables manufacturers to effortlessly and promptly modify their storage capacity, aligning it with their evolving requirements.

This adaptable feature helps businesses use resources efficiently. It means they only pay for the storage space they actually use, avoiding extra costs. Furthermore, the incorporation of cloud-based storage infrastructure not only modernizes the conventional approach of data storage but also significantly amplifies the availability of critical documentation within a business organization.

By using cloud document storage, employees can access important documents and information worldwide at any time. This surpasses the restrictions of traditional storage systems, allowing workers to be productive from anywhere. This increased flexibility encourages remote work culture, enhancing collaboration among team members in various locations.

Data Security and Disaster Recovery

All manufacturers acknowledge the significant impact of unplanned downtime on their operations. Despite its inevitability, many manufacturers are not utilizing all possible strategies to mitigate it.

A recent report by the Engineering Employers’ Federation (EEF) reveals that 45% of manufacturers have faced cybersecurity issues affecting their operational systems. To safeguard sensitive manufacturing data, businesses should employ a range of robust security measures such as advanced encryption protocols and the implementation of multi-factor authentication mechanisms.

Using cloud storage makes sensitive data more secure and helps organize digital documents for manufacturing processes to run efficiently. The cloud enables manufacturers to securely store, access, and manage digital assets with unparalleled ease and minimal interruptions.

Implementing Manufacturing Document Management Software

Implementing an automated document management system is a critical step in digital transformation for any industry. A DMS allows manufacturers to store, manage, and track digital documents, improving efficiency and productivity.

Best Practices and System Integration

In the modern manufacturing landscape, integrating software is vital for enhancing operational efficiency. Software integration minimizes errors, trims manual tasks, boosts precision, and improves collaboration across departments and supply chains.

To achieve effective integration, it is crucial to standardize and centralize data. This entails establishing consistent data formats and ensuring data accuracy across all systems to enable seamless integration.

Compliance with data standardization guidelines streamlines data sharing, reduces redundancy, and enhances data precision. In manufacturing, upholding uniform data standards is crucial for efficient monitoring and upkeep, optimizing operations, and minimizing downtimes.

Workflow Automation Through Document Conversion

Transitioning from paper-based documents to digital files is crucial for enhancing business processes. The automation of tasks such as data entry, invoicing, and document distribution through digital means streamlines operations across departments.

For instance, accounting teams can greatly benefit from AP automation workflow tools, which facilitate the elimination of manual data entry and expedite the approval processes. The result is not only time savings but also a significant reduction in errors, leading to enhanced operational precision and efficiency.

Similarly, departments in charge of accounts receivable can harness a digital mailroom solution to electronically convert and distribute incoming invoices, thereby accelerating bill payment processes. This ensures payments are made promptly, providing an opportunity to take advantage of early discount payments.

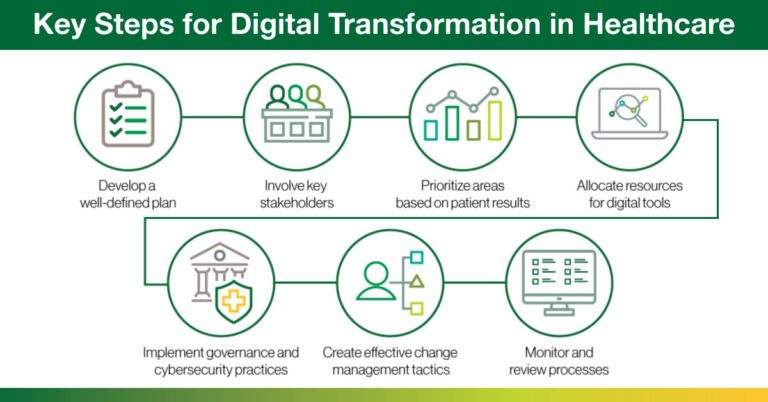

Overcoming Challenges in Digital Transformation

Digital transformation in manufacturing is not without challenges. These include resistance to change, lack of technical skills, and paper-based processes that can lead to a disconnected factory.

Leadership and Change Management

In the realm of digital transformation, strong leadership is crucial for guiding organizations through the complexities of modernization. Leaders must possess clarity, vision, and adaptability to navigate the evolving digital landscape effectively.

To drive successful digital transformation, leaders must communicate and demonstrate the benefits of this journey. Engaging with employees at all levels, seeking their input, and fostering inclusivity can help mitigate resistance to change. Empowering employees to take ownership and be part of the transformation process creates a shared vision that aligns the organization toward its digital goals.

Effective change management strategies are essential for a smooth transition to digital maturity. Providing employees with the necessary support, tools, and resources proactively can alleviate fears and uncertainties associated with significant changes. Offering guidance and assistance instills confidence and encourages employees to see change as an avenue for progress and innovation.

Technology Adoption

Remaining abreast of rapid tech advancements presents an ongoing challenge. Seamless integration with existing enterprise systems is imperative but poses skillset challenges for IT personnel.

The shift to cloud-based infrastructure requires significant alterations in infrastructure requirements. IT teams must manage data migration, security protocols, access controls, and new responsibilities while navigating outdated software licenses from older platforms.

Given the rapid pace of technological advancements in the manufacturing sector, prudence is advised when contemplating substantial technology investments that may become obsolete in a short span of time. Engaging with flexible data management companies that are proficient in introducing and adopting emerging tech trends can mitigate the strain of constant IT upkeep and facilitate simpler system integrations.

Paper-Based Processes

Maintaining an efficient audit trail is crucial to complying with audit requirements. As digital and remote audits become more prevalent, it is essential to eliminate paper-based procedures. Manufacturers seeking real-time insights and data-driven decision-making must avoid paper-based practices.

Businesses in the industry should streamline workflows, improve data collection, and prioritize efficiency and safety by reducing paper reliance. Relying on paper can overwhelm workers and lead to errors in production settings where changes are frequent. The workload associated with paper-based documents in manufacturing quickly becomes unsustainable and could impact future product handling.

Leveraging digital transformation optimizes operations by minimizing errors, automating quality control, and effectively tracking changes. This enhances manufacturing document management, boosts equipment utilization, and streamlines workflows. Through paperless manufacturing and standardized procedures, workers receive precise information promptly, fostering task-oriented performance and reducing errors.

Case Studies: Digital Transformation Success Stories

Several manufacturers have successfully embraced document conversion and digital transformation.

For instance, a leading automotive dealership implemented manufacturing document management software, converting all their paper-based documents into digital formats. This led to significant improvements in their process efficiency and compliance management.

Another example is a global electronics producer that adopted secure cloud storage for manufacturers for their digital files. This move not only improved their document accessibility but also enhanced their data security and disaster recovery capabilities.

The Future of Manufacturing Document Management

The future of manufacturing document management is promising. With advancements in technology, companies can expect more sophisticated and efficient document management systems.

Emerging Trends and Continuous Innovation

With the fusion of document management systems and Internet of Things (IoT) devices, plus the utilization of big data analytics, the landscape of manufacturing document management is on the brink of a profound transformation.

Ongoing innovation is essential for proactively adapting to these trends and harnessing their potential to drive business expansion.

Aligning Strategy With Business Goals

When strategically planning for upcoming ventures, manufacturing companies must seamlessly blend their document management strategy with their overall business goals. This integration guarantees that their investment in document management and cloud-based storage solutions drives them toward long-term success.

Utilizing document conversion and cloud storage services, such as those offered by reputable providers like Vital Records Control (VRC), offers substantial advantages to manufacturing businesses across various industries.

VRC enables cost savings and operational enhancements at every stage of the information lifecycle, making it a reliable choice for companies aiming for efficient and compliant management of physical and digital data.

Learn more about our Manufacturing Document Management Systems.